Carriage board laminating machine

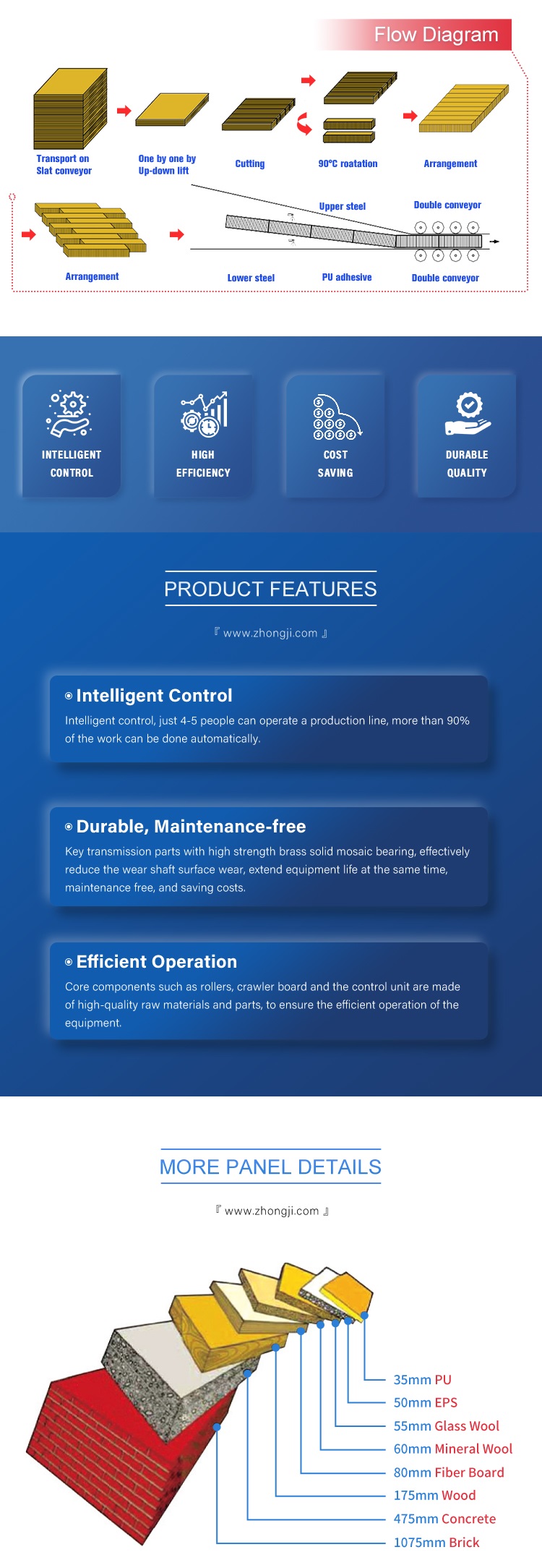

The production equipment for non-continuous polyurethane sandwich panels/refrigerated carriage panels has a size of 3.5 meters x 14 meters, adopts a bilateral entry and exit form, and the host can tilt; At present, it is the most advanced large-scale special equipment for hot adhesive pressing plate of composite panel of Box truck in China, which can produce cold storage panel and large compartment panel. The equipment is composed of a host frame, a left and right mobile conveying platform, a loading template, a hydraulic driven lifting platform, a hot pressing plate heating system, a PLC control system, etc.